How to connect them properly?

1.1. General information – Why differential outputs?

CSMIO/IP devices were designed to be maximally reliable and resist interference. In an industrial environment, electromagnetic interference is often very high. Signals that control the axes' motion - STEP/DIR are the most exposed to the influence of interference because these are very fast signals, especially in CSMIO/IP-S controller – up to 4MHz.

CSMIO/IP devices were designed to be maximally reliable and resist interference. In an industrial environment, electromagnetic interference is often very high. Signals that control the axes' motion - STEP/DIR are the most exposed to the influence of interference because these are very fast signals, especially in CSMIO/IP-S controller – up to 4MHz.

Professional motors controllers (both servo and stepper) have STEP/DIR inputs properly prepared to connect them in a way that is resistant to outside interferences. This is done by so-called differential signals, which are incomparably higher resistant to interference.

Differential connection is made with twisted pair of cables which means that every signal needs two cables – positive (+) and negative (-). It has nothing in common with power, so, e.g., (-) signals cannot be connected with the GND of the device because, this way, the device will be damaged!

Someone can say that we have just mentioned reliability and now the threat of damage. As it happens in life – something for something. Fast differential outputs can be protected like regular, other I/O signals. Differential lines must have standard parameters, which would change if additional protection components were used. On the other hand, if we use regular outputs, then the connection of many professional drives would be almost impossible. Some drives have optically isolated inputs with so-called optocouplers – in this case, both regular and differential signals can be connected. However, many drives have so-called differential line receivers on the fast inputs and then a regular signal connected will cause impulses dropping and positioning errors.

In summary, differential outputs are the option that is the most resistant to interference. It is also the most universal solution, but attention should be paid while connecting because it is easy to damage these outputs if we do it incorrectly.

1.2. Signs used in this guide

![]() Such a connection will not cause damage and will work properly.

Such a connection will not cause damage and will work properly.

![]() Such a connection will not cause damage but it will not work properly.

Such a connection will not cause damage but it will not work properly.

![]() Such a connection will cause CSMIO/IP hardware damage.

Such a connection will cause CSMIO/IP hardware damage.

2.1. Motors drivers with optocoupler input

Optocoupler input is the best available option regarding resistance to interference and convenience of connection. For each signal, twisted pair of cables are needed. Of course, to connect a larger number of axes, you can use cables with more pairs – e.g., a computer network cable has four pairs, so you can connect STEP+/STEP- signals and DIR+/DIR- for two axes.

If the motor driver has optocoupler inputs, then there is no need to connect the GND of the devices too.

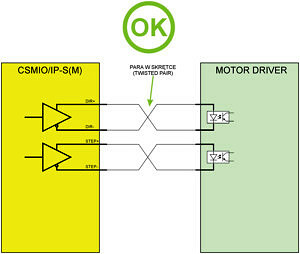

2.1.1. Proper connection to optocoupler inputs

Signs on the drive may differ so you should first read the documentation carefully. It can be, e.g., PUL+/PUL- and SIGN+/SIGN-; however, it is not a rule. Servo drives often have two different types of STEP/DIR inputs - however, usually (not differential) to work on low frequencies and the second for high frequencies. We always use differential inputs for high frequencies, even if we work with slower CSMIO/IP-M.

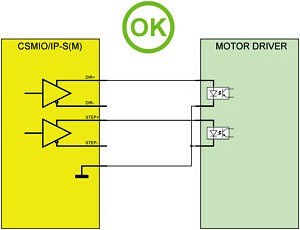

2.1.2. Proper connection to optocoupler inputs with shared cable

This variant is a bit worse because of lower interference resistance and is a bit more difficult to connect.

In this case, we do not use twisted cable, which is why the connection is more exposed to the influence of interferences. A shared cable (cathode) is connected to the GND of the device; in the CSMIO/IP-S, it is the 13th PIN of the STEP/DIR connector, and in the CSMIO/IP-M we have to use the GND on the 2nd PIN or ANALOG I/O 8 connector because there is no GND PIN on STEP/DIR connector.

![]() It is important not to connect STEP- and DIR-pins with the GND of the device because it will cause short circuits and output stages damage.

It is important not to connect STEP- and DIR-pins with the GND of the device because it will cause short circuits and output stages damage.

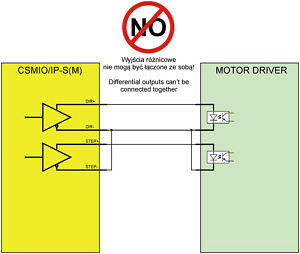

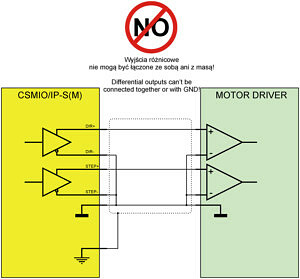

2.1.3. Incorrect connection to optocoupler inputs sample

![]() Because of the short circuit between STEP- and DIR- signals in such a connection, the CSMIO/IP controller will be damaged. The warranty does not cover damages caused by incorrect connection!

Because of the short circuit between STEP- and DIR- signals in such a connection, the CSMIO/IP controller will be damaged. The warranty does not cover damages caused by incorrect connection!

2.2. Motors drive with a differential line receiver

It is a very often used solution because line receivers are less expensive than fast optocouplers, so drives manufacturers prefer them.

However, the reliability of this solution is on a very high level. The difference in relation to optocouplers is the necessity of additional GND of the device's connection and shielding is needed even for short connections.

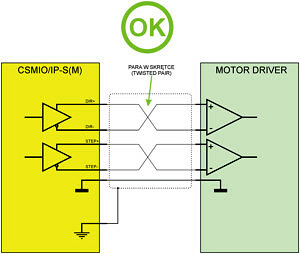

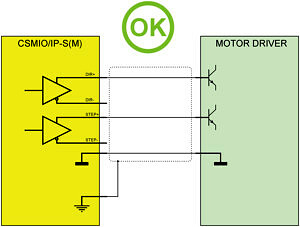

2.2.1. Sample of proper connection of the inputs and differential line receiver

As you can see in the scheme above, the connection is very easy. This example applies to a single drive, but the others we connect the same way, and do not forget to connect GND to all the drives.

The shield is available on the connector's cover in CSMIO/IP-S(M). Shielding should be connected only from the side of the CSMIO/IP controller.

GND in the CSMIO/IP-S is on the 13th PIN of the STEP/DIR connector; in the CSMIO/IP-M, we have to use the GND on the 2nd PIN or ANALOG I/O 8 connector because there is no GND PIN on the STEP/DIR connector.

2.2.2. Incorrect – lack of devices GND connection

![]() Such a connection will not cause any damage but it will not work properly. Moreover, work results can be weird as positioning errors will appear and hide the next minute. The GND of devices must be connected even if all seems to work fine without it.

Such a connection will not cause any damage but it will not work properly. Moreover, work results can be weird as positioning errors will appear and hide the next minute. The GND of devices must be connected even if all seems to work fine without it.

2.2.3. Incorrect – GND and shielding connection

![]() Such a mistake can also be unnoticed for a long time. In some cases, it does not cause any visible problems. However, GND and shielding should not be connected. Negative effects, in this case, can be noticeable from time to time, then it is hard to find them if we do not know the reason.

Such a mistake can also be unnoticed for a long time. In some cases, it does not cause any visible problems. However, GND and shielding should not be connected. Negative effects, in this case, can be noticeable from time to time, then it is hard to find them if we do not know the reason.

2.2.4. Incorrect – both-sides shielding connection (loop)

![]() This quite common mistake appears during installation and usually does not cause visible, negative results (especially with short cables). However, this connection is a mistake that can show up in some specific situations.

This quite common mistake appears during installation and usually does not cause visible, negative results (especially with short cables). However, this connection is a mistake that can show up in some specific situations.

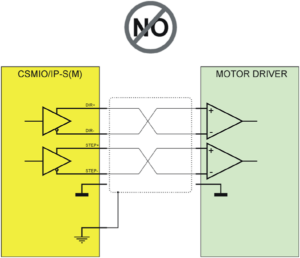

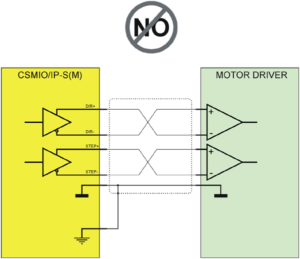

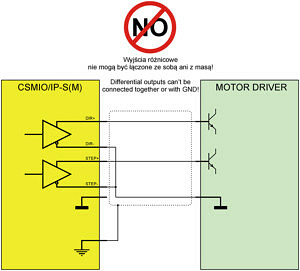

2.2.5. Incorrect – connection of STEP- and DIR- signals

![]() This connection causes CSMIO/IP hardware damage! The warranty does not cover damages caused by incorrect connection!

This connection causes CSMIO/IP hardware damage! The warranty does not cover damages caused by incorrect connection!

The DIR and STEP signals are not the GND, and you cannot connect them. It causes short circuits and damage to the output stage in the CSMIO/IP device.

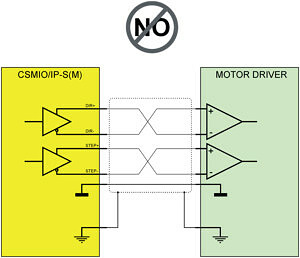

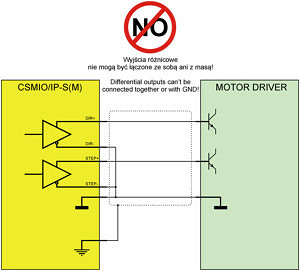

2.2.6. Incorrect – connection of the STEP- and DIR- signals to the GND

![]() This connection causes CSMIO/IP hardware damage! The warranty does not cover damages caused by incorrect connection!

This connection causes CSMIO/IP hardware damage! The warranty does not cover damages caused by incorrect connection!

The DIR and STEP signals are not the GND, and you cannot connect them. It causes a short circuit and damage to the output stage in the CSMIO/IP device.

2.3. Connection to transistor inputs

Transistor-type inputs are less common. It is not the best solution because of quite low resistance to interferences and lack of galvanic isolation. These STEP/DIR inputs are intended for low frequencies of about 250kHz.

![]() You should pay attention to the used voltage standard because sometimes happens that these types of inputs are in 24V standard. Differential outputs of the CSMIO devices work in 5V standard, so the connection is impossible. Read the documentation of the drive carefully.

You should pay attention to the used voltage standard because sometimes happens that these types of inputs are in 24V standard. Differential outputs of the CSMIO devices work in 5V standard, so the connection is impossible. Read the documentation of the drive carefully.

2.3.1. Example of correct connection to the transistor inputs

While connecting the CSMIO/IP to the transistor inputs, remember to connect the GND and to leave the STEP- and DIR- outputs unconnected. Shielding is very important.

GND in the CSMIO/IP-S is on the 13th PIN of the STEP/DIR connector; in the CSMIO/IP-M, we have to use the GND on the 2nd PIN or ANALOG I/O 8 connector because there is no GND PIN on the STEP/DIR connector.

2.3.2. Incorrect – short circuit of STEP- and DIR- signals and if were taken instead of GND

![]() This connection causes CSMIO/IP hardware damage! The warranty does not cover damages caused by incorrect connection!

This connection causes CSMIO/IP hardware damage! The warranty does not cover damages caused by incorrect connection!

The DIR and STEP signals are not the GND, and you cannot connect them. It causes a short circuit and damage to the output stage in the CSMIO/IP device.

2.3.3. Incorrect – short circuit of STEP-, DIR- signals and GND

![]() This connection causes CSMIO/IP hardware damage! The warranty does not cover damages caused by incorrect connection!

This connection causes CSMIO/IP hardware damage! The warranty does not cover damages caused by incorrect connection!

The DIR and STEP signals are not the GND, and you cannot connect them. It causes a short circuit and damage to the output stage in the CSMIO/IP device.

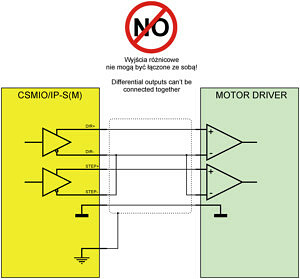

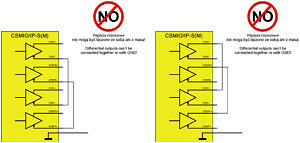

2.4. Common mistake while connecting drives for several axes

„-” and „+” signs placed next to the STEP/DIR signals labels do not imply neither power or anything like that. These signals cannot be connected in any case because it will cause damage to the outputs stage of the CSMIO/IP controller.

In the scheme below, incorrect connections were shown that cause the failure of any device with differential line transmitters, which are also CSMIO/IP-S and M.

While users connect “plus” signals relatively rarely, they connect “minus” signals quite often as they confuse them with the GND of the device.

3. Summary – short author’s note

When installing a complete control system for a CNC machine, we very often connect with each other components that have a high value. That is why it is worth spending some time analyzing the documentation of the devices we will use. While many installations and launches for our customers, I have made more than one expensive mistake myself. To exclude situations like that, you should avoid the rush and do your work as carefully as possible.

You should remember that any electronic device is not fully resistant to incorrect installation. Some mistakes only cause the whole system to not work properly, and some of them, unfortunately, will cause damage to one or more components. Details are most important in these types of systems. Not so long ago, I even thought by myself that things like shielding connection or grounding should have no bad influence on how the CNC machine control system works. The practice shows something else. Every detail matters if we want our control system to work perfectly and reliably. Users that have less experience should particularly spend more time with the documentation of ale the devices they will use. In addition, the Internet is a valuable source of useful information. However, you should be careful of what source you will use because – especially on forums there is much unprofessional advice.

Was this article helpful?

That’s Great!

Thank you for your feedback

Sorry! We couldn't be helpful

Thank you for your feedback

Feedback sent

We appreciate your effort and will try to fix the article