Working on a CNC machine we are not able keep watching the treatment process for example because we have some other work to do or we use more machines at the same time.

In this situation some basic information source if the machine still works or it is idle or in reset state would be very helpful. To verfify the state of the machine without getting close to it we can mount stack lights - a signal tower on it that is visible from a long distance.

Stack light - Signal tower (from CS-Lab offer)

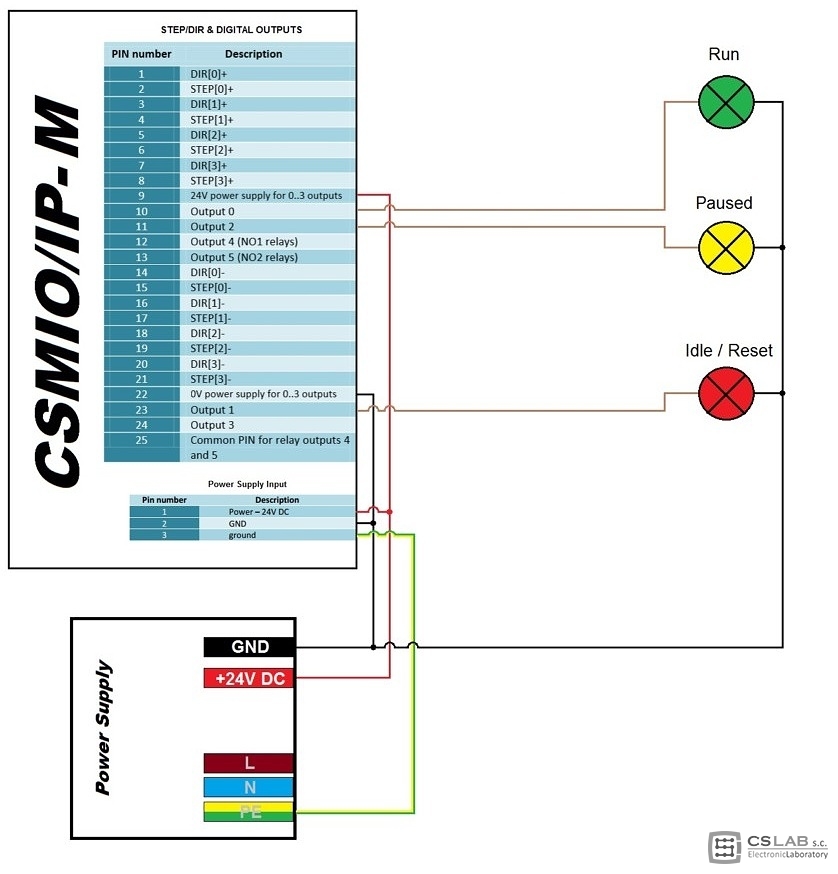

When we get such a tower we need to connect it properly to the CSMIO/IP controller. Below - sample schemes for each type of controller:

» Open PDF file forlarger drawing details

» Open PDF file for larger drawing details

As you can see on the schemes the connection is easy and quick to do. To control the colored bulbsor LEDs of the signal tower we need to use three (3) digital outputs, in my case I decided that:

- digital output no.0 controlls the green light - digital output no.1 controls the red light - digital output no.2 controls the yellow light(For direct bulbs or LED connection to the digital outputs you must remember that the outputs have 250mA max. permissible operation current.)

Basing on our experiences with CNC machines and ready-made solutions in branded machines I have assumed that the lights colours of the tower will have the following meaning:

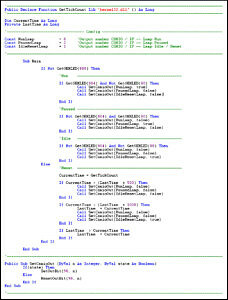

- Green light means that the muchin is running (Run). - Red steady light means that the machin is in idle state (Idle). - Red blinking light means that the machine is in reset state (Reset). - Yellow light means that the machine was stopped on request and is in pause state (Paused).Signal tower control was made by logical conditions placed in macropump. For those who are less familiar I would like to explain that the macropump is a macro, that is running constantly (while loop) in the Mach3 programbackground. Thanks to this macropump feature we can control the signal tower automatically as the logical conditions are all the time verfied and done optionally.

![]() Macro for signal tower download

Macro for signal tower download

Below - the macropump content, as you can see it includes a separate area described as „Config”, here we choose which digital outputs of CSMIO/IP controller will be responsible for the signal tower control (Notice!!! the macropump directly refers to digital outputs of CSMIO/IP controller so the outputs configuration in „Config\Ports and Pins\Output Signals” is unnecessary and even completely excluded.

Click on the picture to enlarge >>

The Macropump that is macropump.m1s file should be placed in „C:\Mach3\macros\name of the file we use” folder, so it could start running we have to only activate „Config\Generlal Config\Run Macro Pump” function and restart Mach3.

I would like to present - as an interesting fact - a solution we used in our small training and demonstration EMCO compact 5 lathe. As our main goal during this machine retrofit was to show Mach3's capabilities - we created an operator panel with backlit control buttons on it.

A button calls out the functions which it has assigned and the backlight is information for macropump if Mach3 made the function or not. This is the same solution as for the signal tower (for the picture all buttons were back-lighted).

Was this article helpful?

That’s Great!

Thank you for your feedback

Sorry! We couldn't be helpful

Thank you for your feedback

Feedback sent

We appreciate your effort and will try to fix the article